Pneumatic Conveying Ash Equipment

Position: TaiSheng > Pneumatic Conveying Ash EquipmentPneumatic Conveying System

This is common pneumatic conveying equipment, simple structure, operation rate high, decorate flexible, convenient maintenance, strong adaptability to the outside environment etc, widely applied in powder material conveying of cement, electric power, metallurgy, chemical industry. (Such as coal fired power plant of fly ash, desulfuration ash, circulating fluidized bed sand and furnace bottom slag, limestone flour, pebble coal, quartzite, soda ash and others material)

We are offering warehouse pump (transmitter) whose inlet valve is by gas seal type top valve, with the unique pneumatic flap rotate valve (introduced Australian technology), all pump (transmitter) inlet valve and level gage use joint ventures or famous domestic brand products. Positive pressure dense phase pneumatic conveying technology to adapt transportation distance for 50-1200m, hoisting height can be up to 75m, system transmission capacity to a maximum of 250 t/h, conveying material temperature is -20~450℃.

Main Features:

1. The equipment is simple, compact structure, flexible process layout, not by topography and space constraints, pipeline layout according to site, realize concentrated, dispersed, high hills, long distance etc.

2.Because whole transportation engineering completely sealed, the weather and environmental effect is small, the material in the course of transmission can avoid moisture absorption, pollution or other material mixed; that guarantees the quality of conveyed material, and at the same time ensure that will not pollute environment, realize cleaner production.

3.The conveying system adopts compressed air for power source, not only achieves high transmission efficiency, but also gets rids of lots mechanical movement mechanism, less malfunctions, low maintenance costs.

4. Control system equipped with pneumatic components mostly, so entire system can implement PLC automatic control.

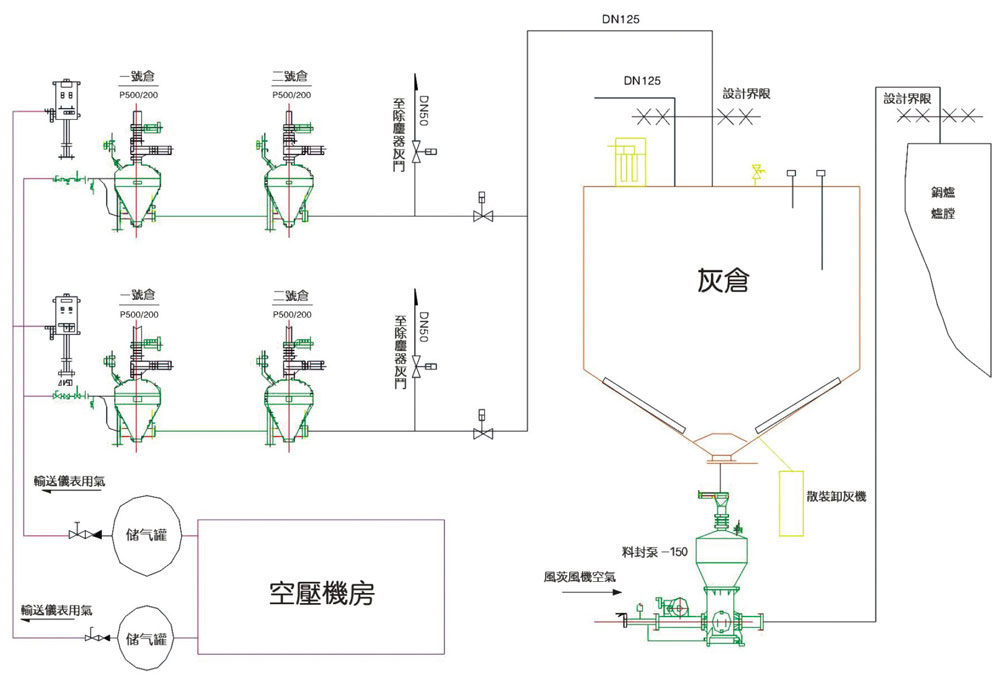

Schematic